Whether you are racing in a spec series or simply for weekend enjoyment, acceleration and speed provide the thrills drivers seek. Other factors, equally as important, such as suspension set-up, braking, and safety are vital in every vehicle application. There is a reason there are not many street cars (or racecars, for that matter) running engines with 5,000 horsepower. Proper vehicle handling is a balance that must be met by focusing on the entirety of the vehicle’s systems. You may have seen entire interiors stripped and gutted, or the occasional car running with no bumpers or lexan windows. To the untrained eye, it may seem counter intuitive to rip out factory upholstery from the car. The (usual) reason for removal of unnecessary items, especially for a car meant for race use, is to remove as much weight as possible. Typical ideas include removal of rear seats, inside panels, and lightweight battery replacement. Once all is said and done, many racers look for uncommon methods to reduce weight for any possible advantage. It is a simple formula, less weight will allow the car to accelerate more quickly, hence faster lap times and less weight roll. For example, if Car A weighs 2,975 lbs. and Car B weighs 3,000 lbs. assuming that both cars are mechanically and aerodynamically identical, it is more probable that Car A will reach a higher speed sooner, even if it is marginal by a few milliseconds.

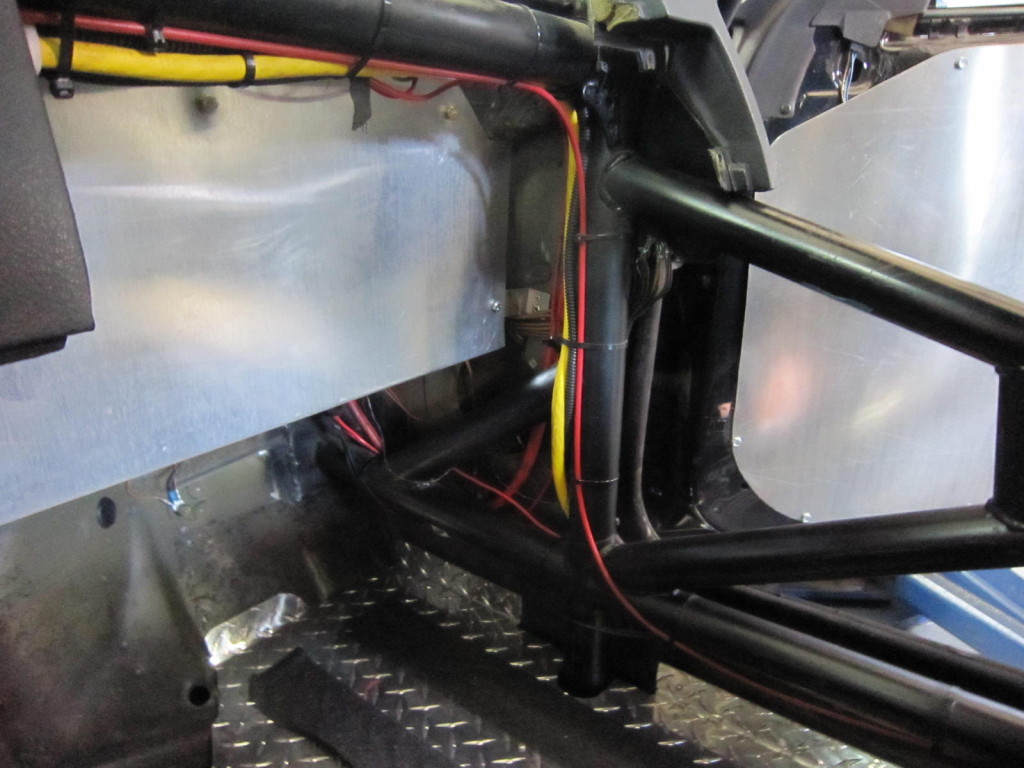

Once the car is gutted, many think of where else they can shave off some weight. As per regulation of many racing sanctioning bodies, cars must be equipped with proper kill switch controls inside and outside of the car. Considering battery location (front, rear, or custom location set-up), proper wiring must be installed and routed to access the kill switch locations in and around the car. Battery-gauge wire is not only heavier than typical wire, it is bulky and heavy-duty due to the amount of high electrical current passing through it. Observe the pictures below to get an idea of a traditional kill switch locations and routing.

Due to the importance of effectively killing electric current and power in the event of an accident, which can cause or aid damage in the event of a fire or crash, there must be no margin for error in the function of these switches. This has been the story for decades, until now.

Here at EUROPERF / Stable Energies, we now carry, sell, and install a new style of kill switch system in solid-state. Instead of pulling, twisting, or breaking off plastic knobs to kill power through long, heavy wire, you can now simply press a small, prominent button to do the job. Not only is this method much simpler to use, understand, and find, it also provides another key advantage: weight savings. This is achieved through the removal, replacement, or rerouting of electric wire from the original set-up. After weighing out the parts removed from the vehicle, a total of over 6 lbs. were saved! Not only is this the latest and greatest in kill switch regulation technology, it also saves a pronounced amount of weight that is vital for any driver seeking that push. Feel free to browse our showroom in Garfield, NJ or give us a call at (973) 773-4870 and we will be glad to assist you with any questions you may have. Drive safe!

Check out the new set-up below: